Mold performance and longevity are the core concerns of the manufacturing industry. The material and design advantages of the inserts lay the foundation for the improvement of mold performance. However, to realize its full potential, it is also necessary to optimize the mold as a whole.

Next, we’ll look at how you can further extend the life of your mold by improving your processes and enhancing maintenance. These combined measures will maximize the value of the inserts.

Insert material and wear resistance?

In mold design and manufacturing, the material selection of inserts is crucial to improve the wear resistance of the mold. By selecting the right insert material, the wear resistance of the mold can be significantly improved, thereby extending the life of the mold and reducing production costs.

- Material hardness: High hardness materials, by improving the resistance of the material itself to deformation, significantly enhance wear resistance.

- Wear resistance mechanism of materials: For different wear types such as abrasive particles, adhesion, corrosion, etc., select materials with corresponding characteristics.

- Insert material selection considerations: Consider operating conditions, cost, and machinability to select the material with the best performance and economy for the application.

- Practical application: Cemented carbide and high-hardness mold steel and other materials improve the wear resistance of the mold and prolong the service life of the mold.

Insert and mold structure?

Inserts play a vital role in the mold structure, not only to optimize the mold design, but also to significantly improve the performance and life of the mold. It has brought significant benefits to the modern manufacturing industry.

- Local Reinforcement & Maintenance: Effectively extend the life of the mold by strengthening the vulnerable areas locally and simplifying maintenance.

- Optimized mold design: Inserts make complex shapes easy to implement, save material costs, optimize mold venting, and improve design flexibility.

- Improve mold performance: Inserts improve the wear resistance, corrosion resistance and cooling efficiency of the mold, and ensure the long-term stable operation of the mold.

- Inlay structure design: The insert makes the mold develop to multi-functional, integrated and large-size, and optimizes the manufacturing process of complex molds to improve the quality of molds.

Manufacture/use with insert effects?

Every aspect of manufacturing and use affects the effect of the insert. In the manufacturing process to ensure the accuracy and quality of the inserts, pay attention to maintenance and maintenance in the process of use, in order to give full play to the advantages of the inserts, prolong the service life of the mold, improve production efficiency.

- Manufacturing precision: high-precision processing and heat treatment to ensure the close fit and excellent performance of the insert and the mold.

- Mold assembly: Precise fit and correct assembly process to avoid loose inserts and performance degradation.

- Use environment: according to the working temperature, corrosive environment and shock vibration, etc., select the insert material and take corresponding protection measures.

- Maintenance: Inspection, cleaning, lubrication and maintenance records to extend the service life of inserts and ensure the normal operation of production.

Table of the relationship between insert material and wear resistance

|

Insert material |

Hardness (HRC) |

Abrasion resistance |

Application scenarios |

remark |

| Tungsten carbide (tungsten carbide) | 70-90 | Extremely high | High-wear, high-impact environments, such as stamping dies, injection mold gates | The cost is higher, but the life is extremely long |

| High chromium cast iron | 55-65 | tall | Moderate abrasive environments, such as casting molds | The cost is moderate and the wear resistance is good |

| Mould steel (D2/SKD11) | 60-64 | Higher | A wide range of high-wear applications such as punches, dies | Excellent comprehensive performance and wide application |

| High Speed Steel (HSS) | 62-67 | Higher | Cutting tools, cold work molds | The cost is moderate and the processability is good |

| stainless steel | 30-50 | medium | Corrosive environments, such as chemical molds | Excellent corrosion resistance, but low hardness |

Product application of inserts

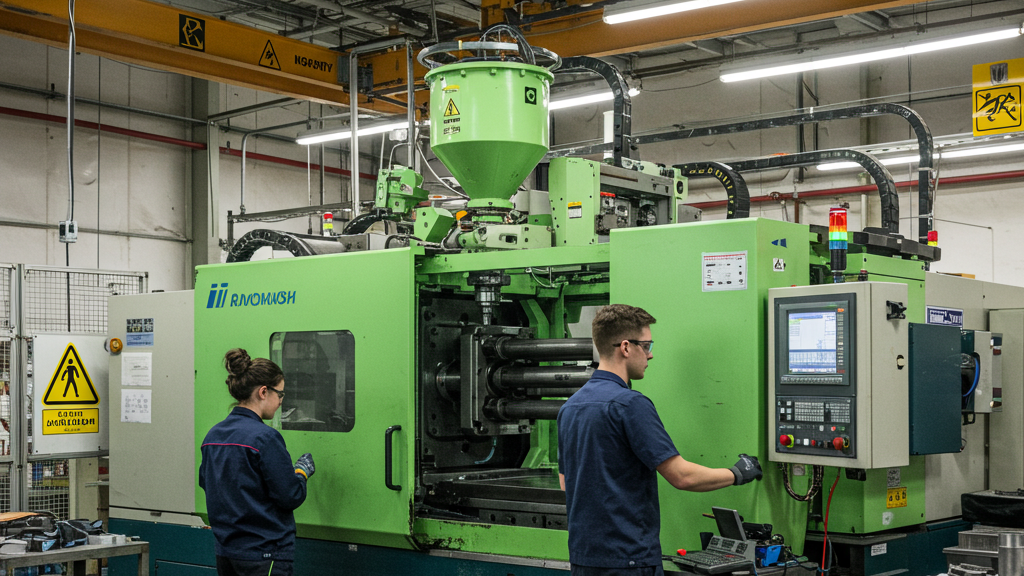

Inserts are widely used in modern manufacturing, where local strengthening, structural optimization, and performance enhancement in stamping and die-casting molds significantly extend mold life and improve product quality.

1.Automotive industry: Inserts are applied in engine parts and body panels, which improves the wear resistance, high temperature resistance and accuracy of automotive parts.

2.Electronics: Inserts are applied in connectors, plugs, and mobile phone housings, which improve the wear resistance, conductivity, and surface quality of electronic products.

3.Medical devices and aerospace: Inserts are used in surgical instruments, medical implants, and aero-engine components to improve the biocompatibility, wear resistance, and high temperature resistance of products.

conclusion

Inlays are used in a wide range of applications and play an important role in improving product performance, extending product life and optimizing production processes. With the continuous advancement of material science and manufacturing technology, the application prospects of inserts will be broader.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Mar-11-2025